Notes from The Lean Startup

Page 20:###

In contrast, if I was interrupted with questions, process, or - heaven forbid - meetings, I felt bad. What did I really accomplish that day? Code and product features were tangible to me; I could see them, understand them, and show them off. Learning, by contrast, is frustratingly intangible.

The Lean Startup asks people to start measuring their productivity differently. Because startups often accidentally build something nobody wants, it doesn’t matter much if they do it on time and on budget. The goal of a startup it to figure out the right thing to build - the thing customers want and will pay for - as quickly as possible. In other words, the Lean Startup is a new way of looking at the development of innovative new products that emphasizes fast iteration and customer insight, a huge vision, and great ambition, all at the same time.

Page 37:

I started to worry about measuring progress in this way. What if we found ourselves building something that nobody wanted? In that case, what did it matter if we did it on time and on budget? When I went home at the end of a day’s work, the only things I knew for sure were that I had kept people busy and spent money that day.

Page 55:

None of these takeaways is especially useful. The Lean Startup is not a collection of individual tactics. It is a principled approach to new product development. The only way to make sense of its recommendations is to understand the underlying principles that make them work. … In other words, we need the scientific method.

Page 109:

Thus, the Lean Startup method is not opposed to building high-quality products, but only in the service of the goal of winning over customers. We must be willing to set aside our traditional professional standards to start the process of validated learning as soon as possible. But once again, this does not mean operating in a sloopy or undisciplined way.

Page 122:

Page 138:

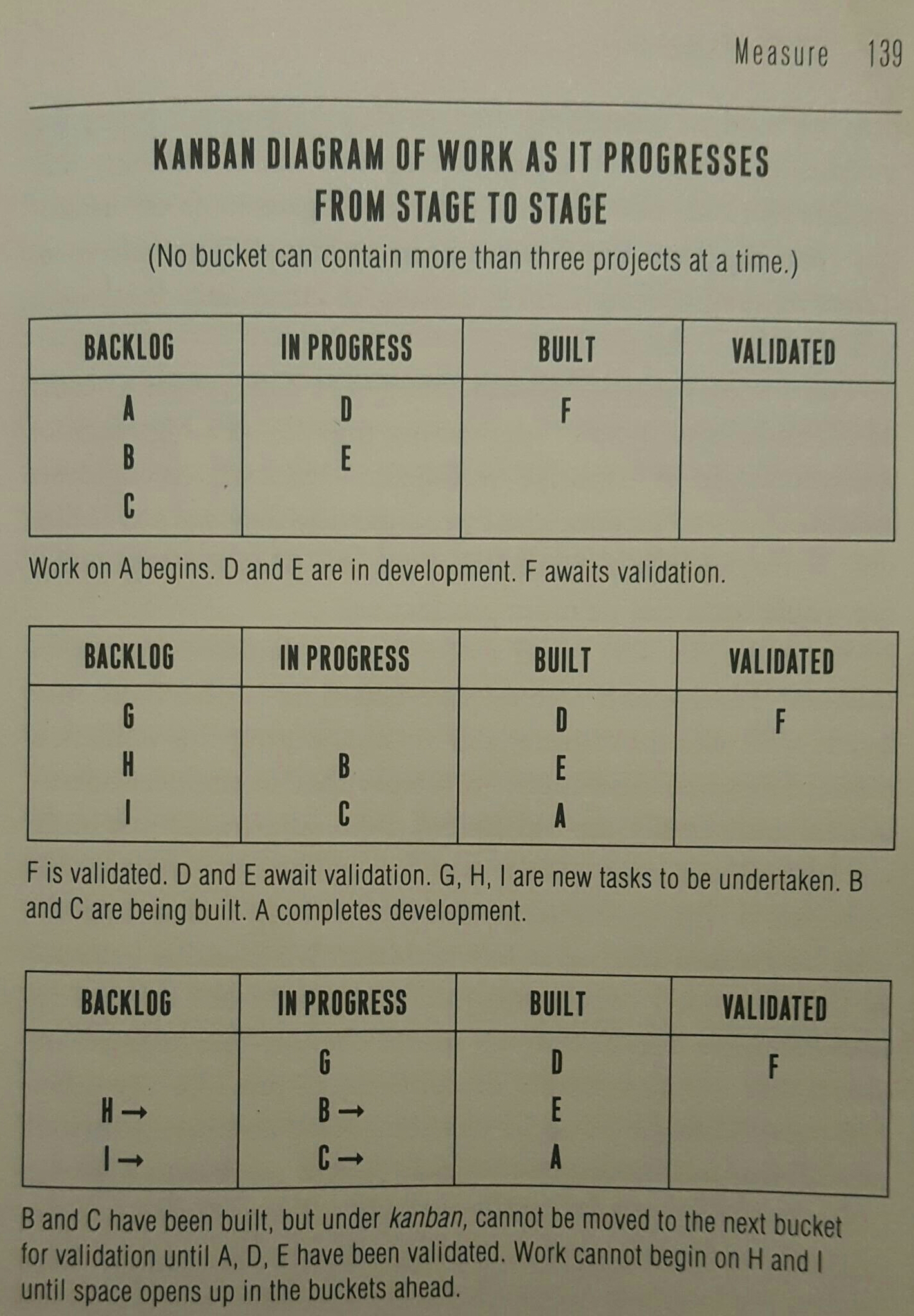

Stories could be cataloged as being in one of four states of development: in the product backlog, actively being built, done (feature complete from a technical point of view), or in the process of being validated.

Page 185:

Why does stuffing one envelope at a time get the job done faster even though it seems like it would be slower? Because our intuition doesn’t take into account the extra time required to sort, stack, and move around the large piles of half-complete envelopes when it’s done the other way. It seems more efficient to repeat the same task over and over, in part because we expect that we will get better at this simple task the more we do it. Unfortunately, in process-oriented work like this, individual performance is not nearly as important as the overall performance of the system.

Page 207:

There are four primary ways past customers drive sustainable growth:

- Word of mouth

- As a side effect of product usage

- Through funded advertising

- Through repeat purchase or use

Page 209:

The three engines of growth:

- Sticky

- Viral

- Paid

Page 230:

When confronted with a problem, have you ever stopped and asked why five times? It is difficult to do even though it sounds easy. For example, suppose a machine stopped functioning:

- Why did the machine stop? (There was an overload and the fuse blew.)

- Why was there an overload? (The bearing was not sufficiently lubricated.)

- Why was it not lubricated sufficiently? (The lubrication pump was not pumping sufficiently.)

- Why was it not pumping sufficiently? (The shaft of the pump was worn and rattling.)

- Why was the shaft worn out? (There was no strainer attached and metal scrap got in.)

Repeating “why” five times, like this, can help uncover the root problem and correct it. If this procedure were not carried through, one might simply replace the fuse of the pump shaft. In that case, the problem would recur within a few months. The Toyota production system has been built on the practice and evolution of this scientific approach. By asking and answering “why” five times, we can get to the real cause of the problem, which is often hidden behind more obvious symptoms.

Note that even in Ohno’s relatively simple example, the root cause moves away from a technical fault (a blown fuse) and toward a human error (someone forgot to attach a strainer). (excerpted from Toyota Production System: Beyond Large-Scale production)

Page 236:

I ask teams to adopt these simple rules:

- Be tolerant of all mistakes the first time.

- Never allow the same mistake to be made twice.

Page 272:

In 1911, Taylor wrote: “In the past, the man has been first; in the future, the system must be first.” Taylor’s prediction has come to pass. We are living in the world he imagined. And yet, the revolution that he unleashed has been - in many ways - too successful. Whereas Taylor preached science as a way of thinking, many people confused his message with the rigid techniques he advocated: time and motion studies, the differential piece-rate system, and - most galling of all - the idea that workers should be treated as little more than automatons … Critically, lean manufacturing rediscovered the widsom and initiative hidden in every factory worker and redirected Taylor’s notion of efficiency away from the individual task and toward the corporate organism as a whole.