Notes from Toyota Kata - Managing People for Improvement, Adaptiveness, and Superior Results

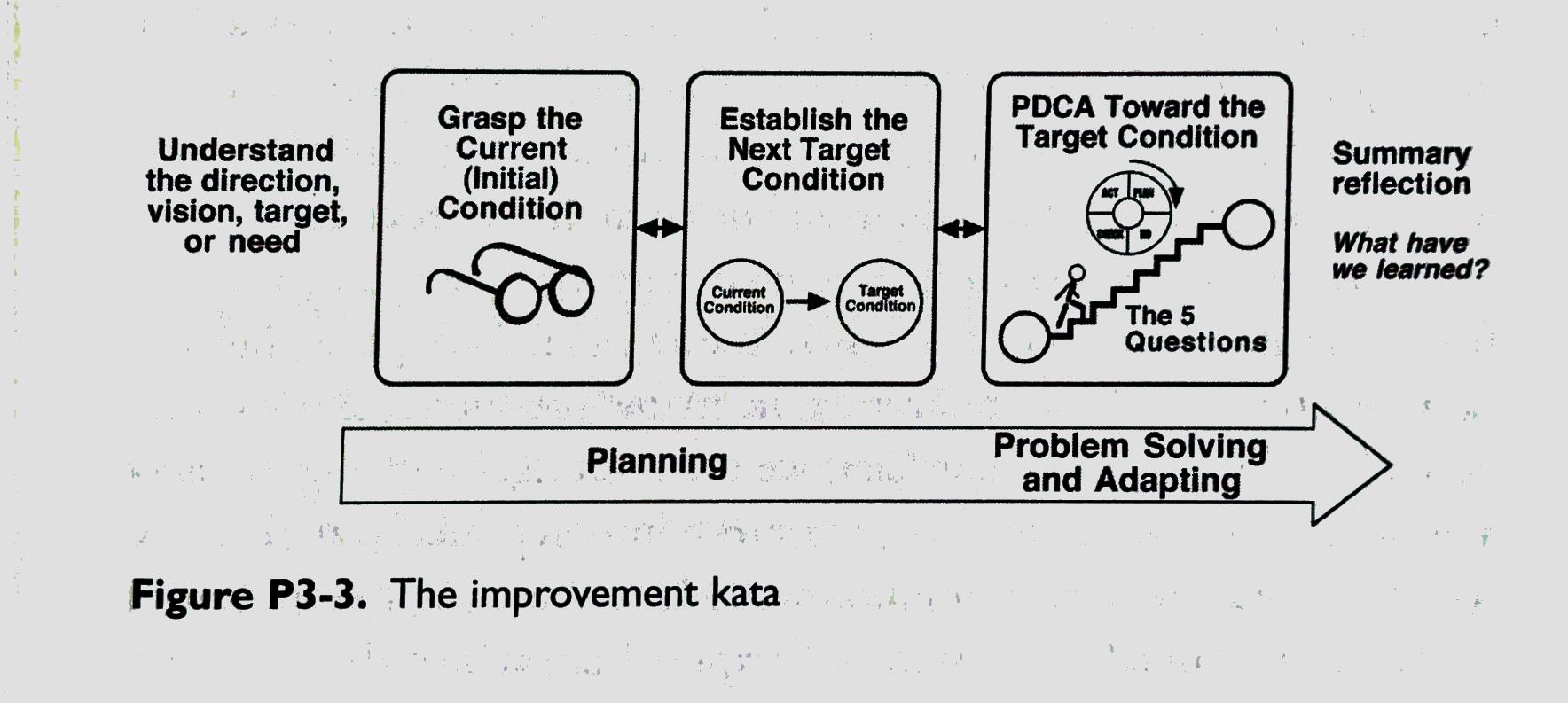

The Improvement Kata:###

Page 6:

The competitive advantage of an organization lies not so much in the solutions themselves - whether lean techniques, today’s profitable product, or any other - but in the ability of the organization to understand conditions and create fitting, smart solutions.

The key point was not the new production techniques themselves, but rather that Toyota changes over time, that it develops new production techniques while many other manufacturers do not.

Page 8:

This is what I mean in this book when I say continuous improvement and adaptation: the ability to move toward a new desired state through an unclear and unpredictable territory by being sensitive to and responding to actual conditions on the ground.

Page 38:

Toyota: survive long term as a company by improving and evolving how we make good products for the customer.

Here are a few questions to help you think about the position of improvement in your organization. Only you can answer them for yourself:

- Do I view improvement as legitimate work, or as an add-on to my real job?

- Is improvement a periodic, add-on project (a campaign), or the core activity?

- Is it acceptable in our company to work on improvement occasionally?

Page 53:

One lesson implicit in this discussion is that we should not spend too much time benchmarking what others - including Toyota - are doing. You yourself are the benchmark:

- Where are you now?

- Where do you want to be next?

- What obstacles are preventing you from getting there?

Remember, the ability of your company to be competitive and survive lies not so much in solutions themselves, but in the capability of the people in your organization to understand a situation and develop solutions.

Page 59:

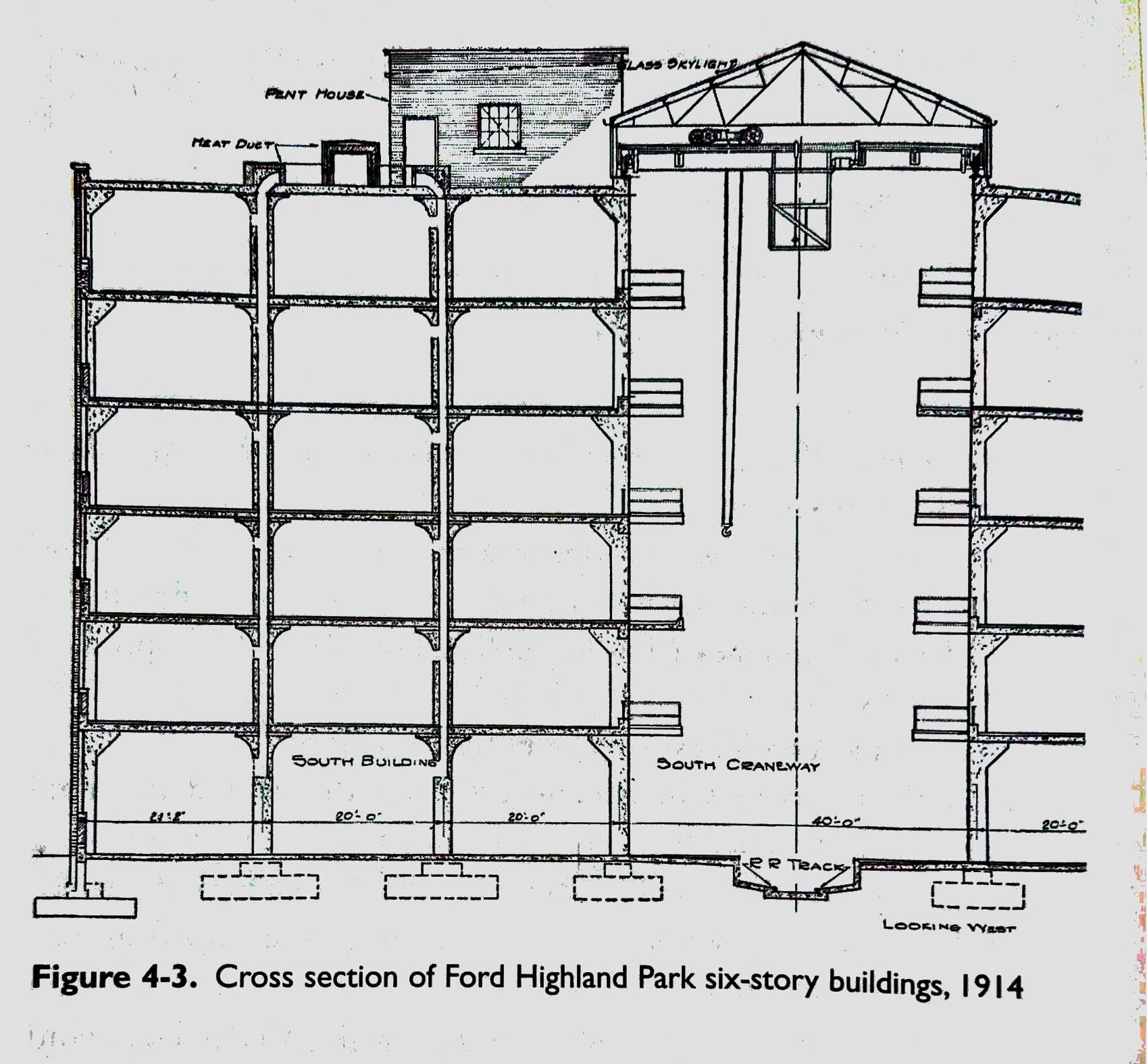

Ford was still a long way from the ideal of a 1x1 flow from A to Z, but that misses this key point: whether consciously or not, by striving to continuously improve the production flow toward an ideal of one connected flow, the early Ford Motor Company was utilization a vision and interim target conditions in a way that highlights critical obstacles and makes them something to be worked through rather than circumvented. This is surprisingly similar to how Toyota’s improvement kata utilizes a long-term vision … to manage people and move the organization forward.

Page 67:

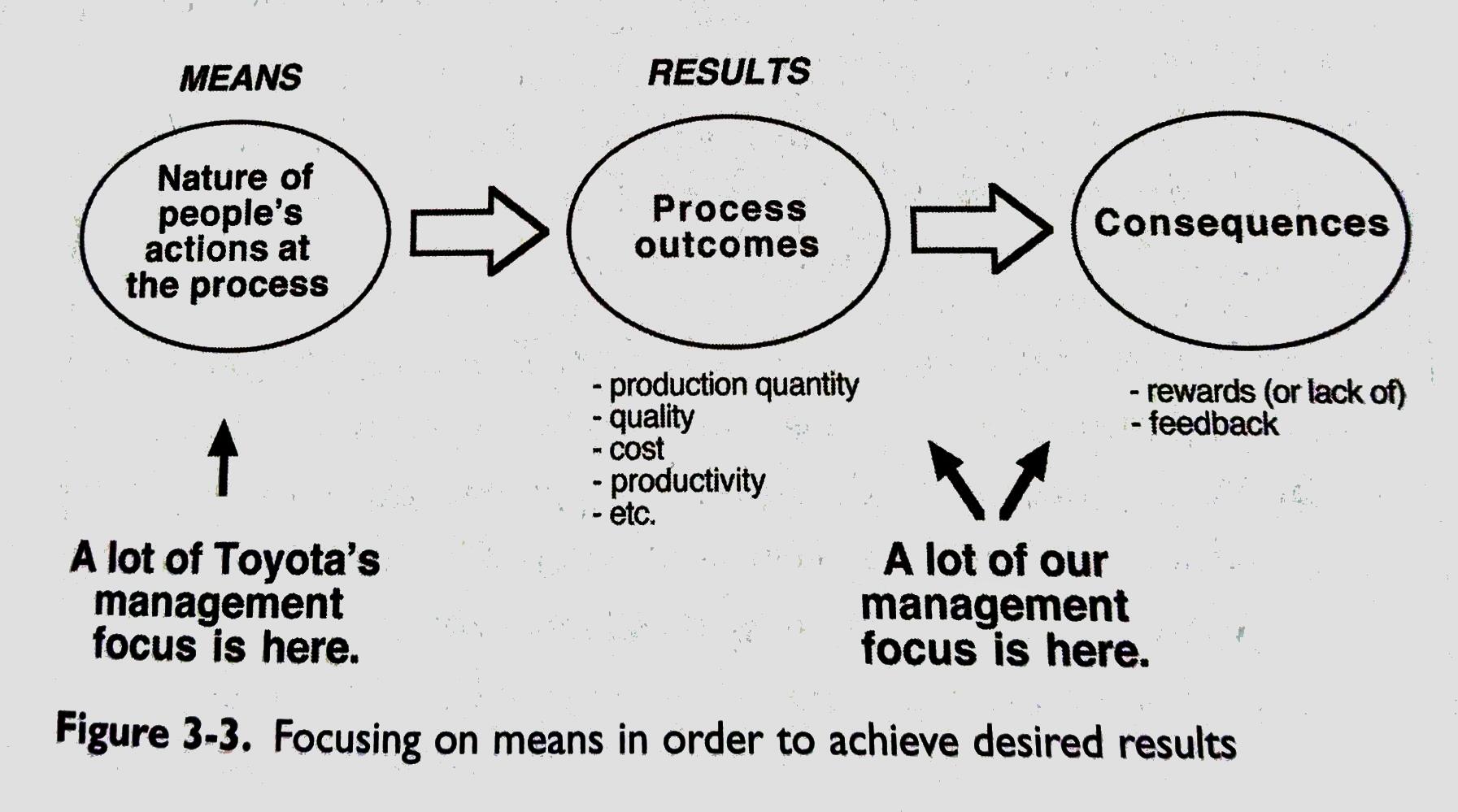

Trying to manage from a distance through data abstractions often results in managers making incorrect assumptions and inappropriate decisions, and trying to make adjustments and adaptations too long after the fact. … Not only are the centrally controlled divisions unable to adapt autonomously and quickly, but the decision makers in the central office are basing their decisions on inaccurate, after-the-fact quantitative abstractions.

The original thinking behind management by objectives (MBO), as outlined by Peter Drucker in his 1954 book “The Practice of Management”, is not too distant from how Toyota is managing. Drucker even mentions, in a short case example, how what he calls “some of the most effective managers I know” go beyond only deploying quantitative targets downward. He briefly describes how these managers engage in a two-way dialog with the level below them in order to develop written plans for the activities that will be undertaken to reach the targets.

Page 68:

Interestingly, moving production to lower-cost countries in order to reduce cost - another form of cutting - does not change the underlying system or improve the production process. Some have called this “making waste cheaper,” because it does not actually change the underlying way of going things.

Page 91:###

“Well, so many things we do at Toyota we do so there is a pattern.” …

- Load the leveling device, the sorter, with kanban according to the intended sequence and maximum lot size specification.

- Ask, “Can we run this way today?”

- If yes, do so. If no, ask, “What is preventing us?” Pursue one problem, and meanwhile temporarily go off the intended sequence. Strive to get back on the intended sequence as quickly as possible.

Page 126:###

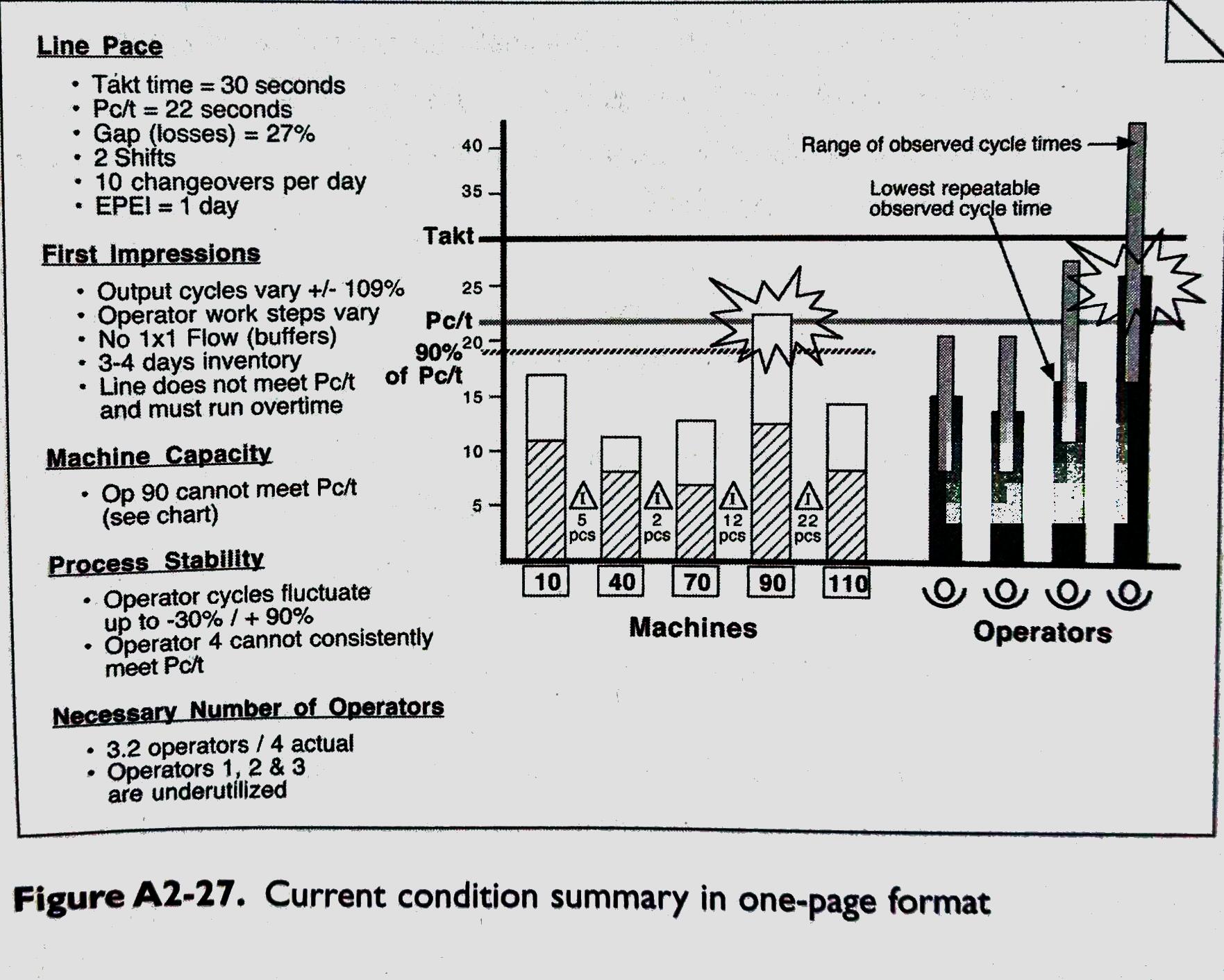

Typical initial target conditions for manufacturing processes:

- Strive to develop a stable 1x1 flow to planned cycle time with the correct number of operators.

- Strive for a level mix with small lot sizes.

- Strive to connect the processes in the value stream to one another via kanban.

- Further improvement.

Page 141:###

Focusing on process instead of blame:

- People are doing their best.

- A problem is a system problem, and if we were the other person, the same problem would still have occurred.

- There is a reason for everything, and we can work together to understand the reason for a problem.

Page 155:###

The Five Questions:

- What is the target condition? (The challenge)

- What is the actual condition now?

- What obstacles are now preventing you from reaching the target condition? Which one are you addressing now?

- What is your next step? (Start of next PDCA cycle)

- When can we go and see what we have learned from taking that step?

Page 191:

If the learner hasn’t learned, the teacher hasn’t taught.

Page 206:

The mentor does not, and should not, have a preconceived solution in mind. The mentor must answer quickly, but he only has to see what the next step is. The mentor cannot fully know the way ahead, but he must grasp the situation deeply enough to know that the next step is so he can lead his mentee to and through it. … In most cases the next step is in fact to get more specific facts or data.

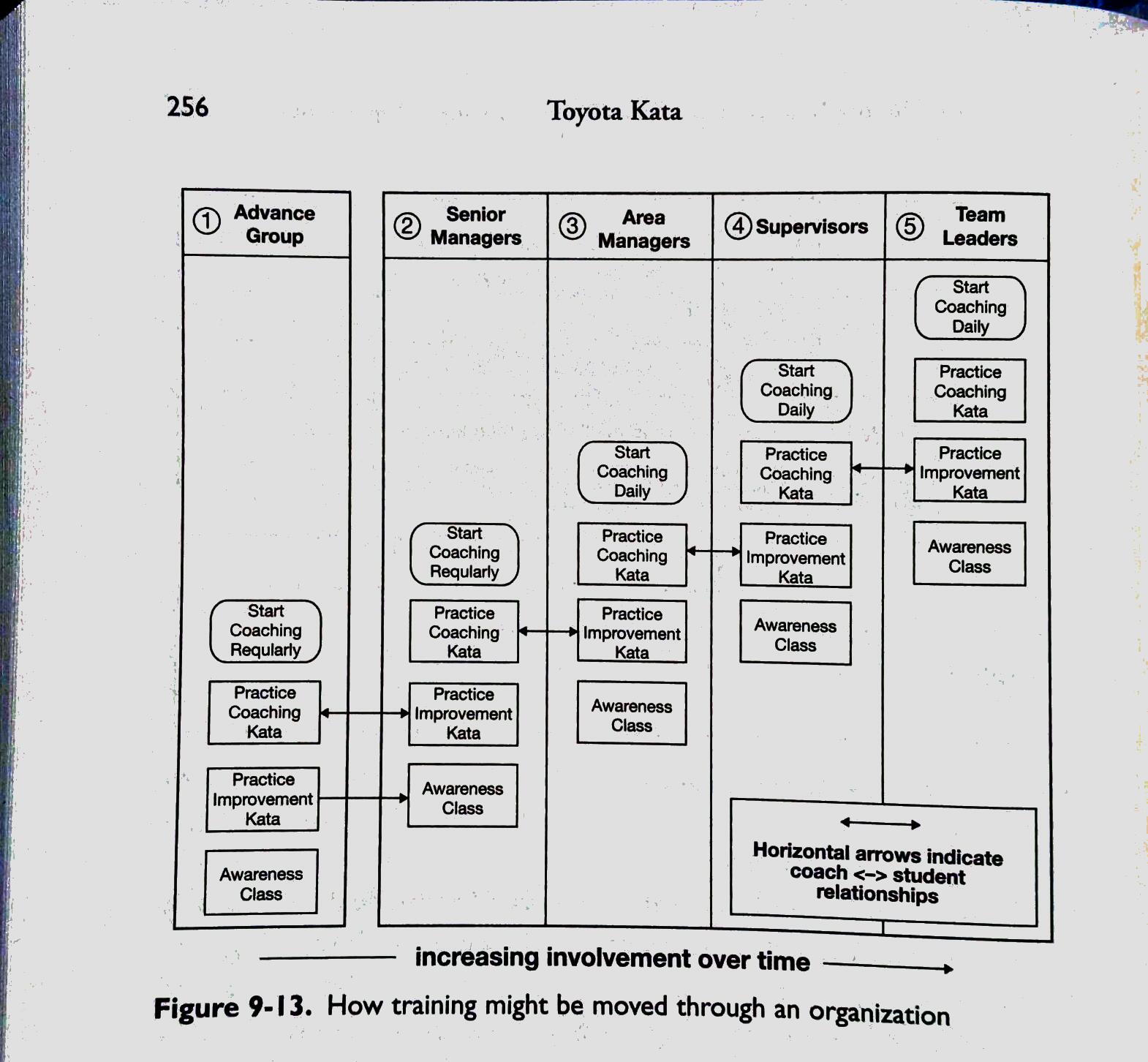

Page 256:

Metrics:

- One set of metrics has to do with coaching. These might be the start and stop times of coaching cycles, how many processes are coached, who does the coaching, how often the coaching cycles take place, and whether the next step (question five) was taken.

- You should monitor the relationship between coaching cycles and … to what degree the focus processes are being improved.

Page 258:###

Begin any reflection session with (1) a restatement of the overall theme (for example, “To develop improvement kata behavior in the organization”), and (2) a reiteration of “why we experiment,” in order to calibrate everyone’s thinking before conducting the reflection.

Page 266:###

The first place in the value stream to establish and drive toward a target condition is at the “pacemaker process,” rather than at upstream “fabrication” processes. The pacemaker process, or loop, in a value stream is the set of downstream steps that are dedicated to a family of products, and where that family of products is finished for the external customer.

Page 271:###

Questions for a Value Stream Scan:

- Which value stream (product family) have you selected?

- What are the processing steps?

- Is the process dedicated (D) or shared (S)?

- At what points along the value stream is inventory kept?

- How does each process know what to produce (information flow)?

- At what processes are changeovers needed?

- What are the loops in this value stream?

- With a one- to two-year time horizon in mind, where:

- Do you think 1x1 flow should be possible?

- Do you think inventory should be replaced with a Pull or FIFO system?

Page 289:###